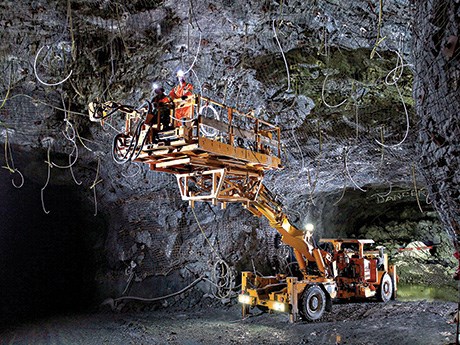

LR3 can work in eight-metre heading and lift up to five tonnes

The LR3 boom lift, the newest addition to MacLean Engineering’s product lineup of underground utility vehicles, makes working at heights a breeze.

A survey of underground equipment in Australia by the Ontario-based manufacturer revealed the need for a high lift, heavy-duty elevated work platform, said utility vehicle product manager Daniel Stern. Prior to the introduction of the LR3, there were a lot of high lift platforms and a lot of heavy duty work platforms, but none that did both.”

One unit is in Australia undergoing trials with a contractor, a second one is on the way.

“It’s like an anfo loader on steroids. It has the same size platform as a scissor lift – 8 foot x 12 foot – but it’s mounted on a telescopic boom,” said Stern. “It can work in an 8 metre heading and lift up to five tonnes. There wasn’t a machine that did that.

The LR3 is ideal for installing big fans in large headings.

“Before,” said Stern, “they’d strap a fan with a purpose-built basket onto a wheel loader, lift it up, and then use a second wheel loader with a man basket to do all the electrical work, but there’s a growing trend in the industry to not put people in baskets and buckets in wheel loaders where there’s a second person controlling the machine.

Stern hopes MacLean Engineering’s customer in Australia will decide to retire its entire fleet of wheel loaders.

“The LR3 is a one man operation,” he noted. “You have all the controls on the platform that you have on a scissor lift. You can lower and lift, but you also have boom swing, which is something fairly unique. In addition, we took the remote drive system from our bolter and SL3 scissor lift and installed it on the LR3, so not only do you have the ability to lift yourself up to a six-metre deck height to work in an eight-metre back, but you also have the ability to remotely drive the machine from up on the deck.”

MacLean Engineering designed the LR3 for the large headings common in Australia, but also sold a unit to Glencore’s Bracemac-McLeod copper-zinc mine in Matagami, Quebec, 250 kilometres north of Val d’Or. The North American version of the LR3 features a lift capacity of four tonnes (8,000 pounds) and a deck height of six metres.

The boom lift works with MacLean Engineering’s Mine-Mate attachments, including fan and pipe handlers, as well as cable pushers and reelers.

“The standard 8-foot x 12-foot deck features slewing capability, so the deck will actually rotate like a turntable,” said Stern.

“That’s important because when you swing the boom over, you want to rotate the deck and keep it parallel with the wall or face. We also have a six-foot x 10-foot man lift basket for installing services and a third deck designed for the Australian market designed to handle twin fans bolted together in parallel.”

The latter weigh in at 9,000 pounds or 4.5 tonnes, said Stern.

The decks can be lowered to ground level and swapped out using a quick coupling system.

MacLean Engineering designed the LR3 for the Australian market but also sees a requirement for the machine in the North American market.

“The main haulage drifts are getting quite large in Ontario, Quebec and Western Canada,” said Stern. “Traditionally, they’d use a scissor truck and build a muckpile to get the height required.” With the LR3, they could get to a six-metre working height without having to go to the trouble of building a muckpile.”