A unique pipe handler designed and manufactured by Sudbury-based Marcotte Mining Machinery Services will make pipe installation safer for underground miners at Climax Molybdenum’s Henderson Mine in Clear Creek County, Colorado, 50 kilometres west of Denver.

A unique pipe handler designed and manufactured by Sudbury-based Marcotte Mining Machinery Services will make pipe installation safer for underground miners at Climax Molybdenum’s Henderson Mine in Clear Creek County, Colorado, 50 kilometres west of Denver.

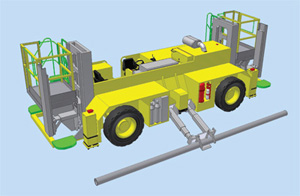

The dual platform machine has four-wheel steering capability, allowing it “to crab up against the wall,” said Marcotte sales and marketing manager Joe Laprairie.

“A similar unit was manufactured in the past, but it had some flaws in it. We’ve made some major improvements to eliminate a lot of the bull work.”

Previous designs required miners to lift the pipes from the ground or bring in a second machine to do the lifting. Marcotte’s pipe handler is equipped with a lifting device that extends out from the side of the unit, grabs a pipe from a pallet and hoists it up to the two platforms.

The unit was designed at the request of the customer and with input from miners, foremen and maintenance staff at Henderson Mine.

“Our engineers thrive on building something new like this. It’s a challenge for them – something they can put their teeth into,” said Laprairie.

Utility vehicles

Marcotte designs and manufactures a wide range of utility vehicles for underground mining, including anfo loaders, flat decks, fuel/lube trucks, scissor lifts, personnel carriers, forklifts, road conditioners and shotcrete sprayers from its 35,000-square foot facility in Sudbury.

Innovation and design improvements can be either customer driven or internally driven, noted Marcotte general manager Denis Rienguette.

It’s always better to have customers involved because the unit is designed to their specifications. “They take pride in it and feel good about it,” he said.

“When you design something internally and want to put it out for testing, it’s 100 per cent at your expense. You have a three quarters to a million dollar machine you’re investing in and it always comes down to which customer wants to be the first one to try it.”

Climax Molybdenum, a subsidiary of Freeport-McMoRan Copper & Gold and the largest primary producer of molybdenum in the world, selected Marcotte for the design of the pipe handler because of the company’s track record for innovation in the past.

The Sudbury equipment manufacturer scored points with Climax Molybdenum several years ago when it designed a boom truck with a man basket to change rollers and perform repairs on the mine’s conveyor system.

“They’re restricted in physical space, so we came up with a concept that gave them a working platform that reduced the physical labour required and fit into the envelope they had,” said Rienguette.

Upswing

Business is recovering nicely from a state of “cardiac arrest” Marcotte experienced following the global financial meltdown in 2008. In order to keep layoffs to a minimum, the company decided to build 10 scissor lifts for stock, and by mid-April all but one were sold.

Ironically, the two-year downturn was the busiest time in the sales department for quoting, said Laprairie. Mining companies “ knew the market was coming back. They were just waiting for metal prices to go up to get their mines going again. We were squeezed for price and now we’re being squeezed for delivery.”

Marcotte currently has 62 employees, but expects to return to its historical high of 85 by July.