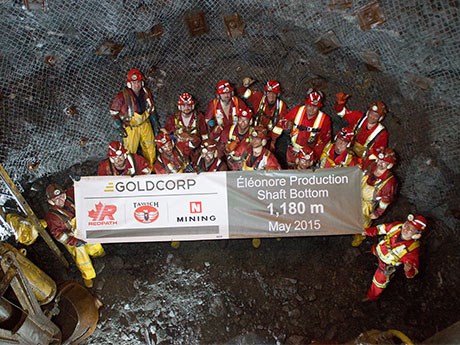

J.S. Redpath Limited, along with joint venture partners Tawich Construction and Norascon Mining, have completed the sinking of Goldcorp’s Éléonore production shaft to a depth of 1,180 metres.

The bottoming out of the seven-metre diameter concrete lined shaft comes on the heels of the earlier completed work by the joint venture for the exploration/ventilation shaft and ramp development, both of which are currently servicing mine building activities.

The production shaft crews achieved a safety milestone of 600 days without a loss time incident or medical aid.

“While this shaft does not challenge the major shafts of the world in depth, it most certainly presented the shaft sinking 18/teams with extraordinary challenges not normally encountered in this type of work,” said Redpath’s Kevin Melong, senior manager, shaft projects.

At project startup, the remote location in the James Bay Lowlands of Northern Quebec had no infrastructure, power or roads.

Joint venture partner Tawich, a Cree construction company from the Wemindji First Nation, worked with Redpath to train “the greatest number of Cree workers in the province of Quebec (to be) integrated into the mining sector.”

The sinking of the Éléonore production shaft “was successfully carried out through very seismically active ground conditions with significant water inflows further complicating shaft sinking efforts,” said Goldcorp’s Éléonore general manager, Guy Belleau. “To sink in excess of 600 days approaching 250,000 man-hours at high productivity levels without an injury is a testament to the strong safety culture and dedication of all who participated in this great achievement.”