Growing a successful consulting business and mentoring young professionals are two of the reasons Bob Rappolt, vice-president of Stantec’s mining practice, was inducted into the Sudbury Area Mining Supply and Service Association’s (SAMSSA) Hall of Fame.

Growing a successful consulting business and mentoring young professionals are two of the reasons Bob Rappolt, vice-president of Stantec’s mining practice, was inducted into the Sudbury Area Mining Supply and Service Association’s (SAMSSA) Hall of Fame.

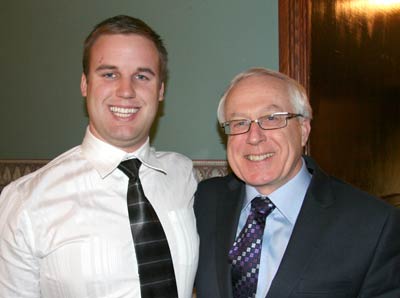

The presentation was made at SAMSSA’s annual meeting December 8th 2010 with Rappolt’s son, Rob, introducing his father to the association’s membership. “It was very emotional for me, especially having my son announcing me as a recipient,” he said.

Rappolt graduated from Queens University in 1976 with a degree in mining engineering. Growing up on a dairy farm in the Cambridge area in southern Ontario, his first exposure to engineering was through his high school sweetheart’s father, who was an engineer.

“I was one of six children and we didn’t have much money. I thought her father was successful and that he did very well in life, so I decided to pursue engineering,” he said.

Once he arrived at university, he decided to specialize in mining because of the diversity of the field. “In mining, you learn a little bit about everything.”

After graduation, he moved north and joined Inco’s Sudbury operation, remaining there until 1987, in which year he joined J.S. Redpath Limited in North Bay.

In 1993, an ownership transition to McIntosh Engineering moved Rappolt into the position of principal and, two years later, he took on the position of president of the company’s Canadian operations.

McIntosh was sold to Stantec in July 2008 and Rappolt was appointed vice-president, mining. His current position focuses on global business development and customer relations.

Rappolt is proud of the success McIntosh achieved in the 15 years before Stantec took over. “The fact that we survived as a small, privately owned company with a limited number of employees is an accomplishment. We survived all the mining cycles between 1993 and 2008 and we watched a lot of competitors come and go. Not only did we survive, but we always maintained or gained market share and the trust of our customers,” he said.

The business strategy targeted the development of clients overseas in 30 different countries. Rappolt has the required finesse for working within different cultural environments. He is proud to claim that the company is a globally recognized leader in underground mine design. He says “good consulting companies don’t have smarter people. They have good people who work with smart customers.”

Rappolt sees a close association between the advancements in technology and the creation of a safer work environment. “By continually improving our technology, we also improve safety,” he said.

“I remember Jim Ashcroft presented a paper on minerless mines,” he recalled. “I may not see a minerless mine in my lifetime, but if we can remove people from risk related environments, that would be the ultimate technological objective.”

Mentoring

Mentoring young people has been a bonus in many ways for Rappolt. “It’s wonderful to watch young people grow. Many people I hired 15 years ago are either doing very well in the industry or have done well in our organization, while others are now customers.”

Mentoring is important because of the huge gap in the talent pool - not just in Canada, but globally. Rappolt sees human resource sustainability as a challenge for the mining industry. There have been times when his company, and others, turned down work because they couldn’t find qualified workers.

Predictions

“If I understood market conditions, I would be retired now,” he chuckled. “I think this is a different cycle. The mining world will never be the same. We have a huge global population. As of 2008, the global population is 6.4 billion with 35 per cent in China and India, two emerging markets that require more metals,” he noted.

“It is different than the 2004-08 cycle when we had base metals and precious metals all spiking. Typically in the industry, some are up, some are down, but potash was just coming into its own as it was spiking. Now, here we are in 2011 and every mineral resource I know of – platinum, palladium, copper, gold, nickel and potash are all peaking.”

“Based on what I have seen in the last 30 years, I think this could be the longest sustained spike in recent memory and not by one commodity, but by all commodities,” he said.