Ground control engineers at Vale Inco’s Creighton Mine in Sudbury have a new virtual reality (VR) tool for interpreting seismicity and proactively addressing potential rockburst hazards.

Ground control engineers at Vale Inco’s Creighton Mine in Sudbury have a new virtual reality (VR) tool for interpreting seismicity and proactively addressing potential rockburst hazards.

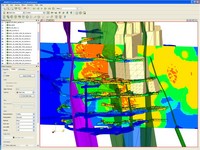

The tool, developed by researchers with MIRARCO Mining Innovation at Laurentian University in Sudbury, collects and interprets data from seismic monitors throughout the mine and uses VR technology to project so-called seismic excavation hazard maps onto a 3-D visualization of the mine’s underground workings.

"If you go back 15 or 20 years ago, everybody did things in 2-D," said Andrew Dasys, vice-president of MIRARCO. "Mining engineers took those plans and synthesized a 3-D image in their minds. Now, we’ve moved to 3-D software. However, mining is not a 3-D problem. The geometry of the mine is 3-D, but it’s dynamic. You’re taking out rock, you’re changing the stress field and, as you’re changing the stress field, the rock wants to go back into a state of equilibrium, so something’s going to shift."

The application of VR helps ground control engineers understand what is happening in the mine and how future underground development will affect the rock mass, "so we’ve gone from 2-D mining, to 3-D mining with much of the commercial software we see out there, and now to 4-D mining by bringing the space-time continuum into the picture," said Dasys.

MIRARCO began working with Inco to apply VR technology to seismic data interpretation in 2001, when Laurentian acquired the VR facility, said Pavel Vasak, who led the research team.

Hazard levels

The seismic excavation hazard maps are colour-coded to represent low, medium and high hazard levels, and integrated with 3-D visualizations of the mine’s geology and infrastructure, allowing engineers to correlate hazard areas with drifts, stopes, ramps and faults.

"The maps identify areas of the mine that may need enhanced support," explained Vasak. "If you have a lot of seismicity in an area, the rock mass is damaged, so you need to ensure that you don’t have a ground fall."

Alternatively, engineers may choose to completely bypass a zone, depending on the severity of rock weakness and the amount of time and effort required to stabilize it.

"The tool allows for insight and understanding," said Dasys. "We tend to think of rock as being monolithic and homogeneous – that it doesn’t change. It’s big, it’s solid, you can’t move it, but it’s not homogeneous. There are different physical properties for different rock types. There is faulting through it. It has structures that move if you allow them to be displaced."

One thing the application doesn’t do is predict rockbursts. That’s the "holy grail," said Dasys.

It will, however, show how the rock mass has reacted to a recent blast or a new stope sequence. "Every time you start mining in a new area, you activate something," said Vasak. "You really don’t quite know what’s going to happen, so what the VR tool does is it takes the data and tries to figure out what is going on. It may actually signify that you have a structure that may potentially cause you some problems."

Rockbursts

Predicting rockbursts in mines is complicated because of the uncertainty in mining. Mechanical and civil engineers deal with engineered materials such as concrete and steel, said Dasys. "They know the exact properties of the materials they’re working with and they make sure there are no flaws, but rock is flawed and we don’t really know how flawed it is until we actually get down there.

"Seismicity identifies where the flaws are and how severe they are, so it gives us a view into the rock mass that we can’t see with the naked eye. It’s a record of rock mass damage."

Vasak, who has a Master’s degree in Geological Engineering from the University of Waterloo and is currently working on a PhD at Laurentian, recalls working on a research project at Creighton and connecting a speaker to the geophone output of the mine’s seismic monitoring system.

"It’s almost like listening to the heartbeat of the mine," he said. "You can hear all the drilling and, when they blast, you can hear each round go off."

Dasys calls it rock music.

Ground movements are recognizable as a flurry of activity, he said. "It starts, builds up and dies down." As with earthquakes, there is never a single event. "There are always aftershocks."

VR seismicity interpretation offers ground control engineers another element of information that helps them to be more proactive, noted Vasak. "Usually you’re fighting fires. Something happens and you have to go and fix it."

VR technology gives you the ability to actually see what’s happening and make a decision before an event. It also offers a broader understanding of rock mass behaviour.

Broader picture

"Traditionally, you’re looking at a small window of seismicity. This gives you the ability to also look at what happened 10 years ago. It gives you a broader picture."

The tool was demonstrated at the official opening of the Golder-MIRARCO Virtual Reality Interpretation Centre in Toronto during the Canada –U.S. Rock Mechanics Symposium, held in conjunction with the Canadian Institute of Mining and Metallurgy conference and exhibition, May 9 to 14.

According to Vasak, interest in VR seismicity interpretation is bound to increase as "we mine out surface deposits, go deeper and mine more structurally complex orebodies."