Historic mining camp sees flurry of acquisitions and staking

Global demand for cobalt has sparked a flurry of acquisitions and a staking rush in the Town of Cobalt and surrounding area. According to Gino Chitaroni, president of the Northern Prospectors Association and Polymet Labs, two factors are driving the demand: the electric vehicle revolution and an expected crackdown on artisanal mining in the Democratic Republic of the Congo (DRC), which supplies approximately 60 per cent of global supply.

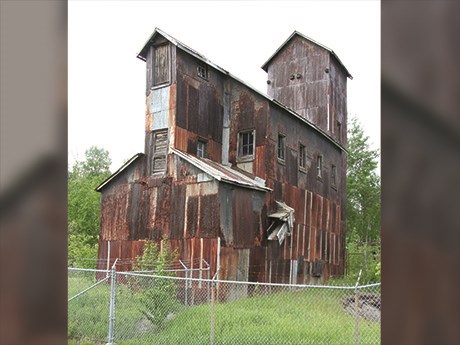

The Cobalt area, famous for ore containing both cobalt and silver, boomed in the early 20th century, eventually yielding a total of 460 million ounces of silver. The peak year was 1911 when 34 mines produced approximately 30 million ounces. Mining activity slowed in the late 1920s, and picked up again in the 1950s. A handful of mines continued to operate through the 70s and 80s, but the area never regained its former prominence and has seen no mining at all for 30 years.

Cobalt was also mined in the area, but was considered “an irritant,” said Chitaroni, because of its high arsenic content. “There aren’t any good stats on how much cobalt was produced in the Cobalt camp because it was never reported, wasn’t recovered, or paid for.”

The sudden surge of acquisitions and staking is the result of “a perfect storm,” he said.

In addition to the Tesla Gigafactory coming onstream this year and some 400,000 people putting down a $1,000 deposit on the company’s battery-powered Model 3 Sedan, pressure is building to address the unsafe working conditions and exploitation of up to 40,000 children working as artisanal miners.

In November of last year, the Chinese Chamber of Commerce for Metals, Minerals & Chemicals with support from the Organization for Economic Co-operation and Development (OECD) launched the Responsible Cobalt Initiative to curb the use of child labour and other abusive practices in the DRC.

Apple, HP, Samsung SDI, Sony and several Chinese companies have joined in the effort and pledged to follow OECD guidelines for mining supply chains, which requires them to trace the source of the cobalt they purchase and how it’s mined. They pledged to work with the DRC to implement an action plan this year.

The initiative was preceded by a Washington Post report in September exposing the dangerous working conditions, child labour and meager earnings of artisanal miners digging cobalt out of the earth to power cellphones, laptops and electric vehicles. Earnings from cobalt mining in the DRC are also used to fund militias in the sprawling, war-torn country.

Also, in November, the Electronic Industry Citizenship Coalition, which includes Apple, Dell, Google, Honda, Microsoft and LG Electronics, among others, announced a Responsible Raw Materials Initiative “to address the most significant social and environmental impacts related to the extraction and processing of raw materials used in the global supply chains of technology companies.”

Cobalt demand is expected to soar, but 94 per cent of global cobalt supply comes from copper and nickel mines that produce cobalt as a by-product. This makes cobalt production dependent on copper and nickel prices, explained Chitaroni.

Lackluster commodity prices for copper and nickel are a disincentive to invest in higher production. As well, the closure of Glencore’s Katanga and Mopani operations in the DRC and Zambia in September 2015 for a projected 18-month period took thousands of tonnes of cobalt out of production.

The only advanced stage primary cobalt project in North America is Vancouver-based eCobalt’s Idaho Cobalt Project. Although fully permitted and partially built, the project was placed on care and maintenance in 2013, and is awaiting the results of a bankable feasibility study this month.

Contingent on the successful completion of the study and subsequent mine financing, re-commencement of construction will start immediately with full production slated for 2019. The Idaho Cobalt Project is expected to produce 1,500 tonnes of high purity cobalt sulfate annually over a 12.5-year mine life.

Tesla, which will consume thousands of pounds of cobalt annually, has pledged to source all of it from North America, but total Canadian production is less than 7,000 tonnes and U.S. production is still marginal.

Junior miners mindful of the impending shortage of cobalt began descending on the Town of Cobalt in the spring of last year, said Chitaroni.

Vancouver-based CobalTech Mining, formerly Big North Graphite, acquired the Duncan Kerr property and its Canadaka Mill from Trio Resources in November. The property contains 6,588 dry tonnes of crushed material resources and 1.3 million tonnes in tailings spread around the site, which it hopes to sell as bulk concentrate.

Cobalt Power Group, formerly the Global Copper Group, also from Vancouver, began acquiring property in the Town of Cobalt in September and has produced a series of press releases announcing sampling programs, geophysical surveys, line cutting and additional staking.

Cruz Capital Corp. has acquired eight cobalt properties, including four in the Cobalt area, but hasn’t reported much work on them. Other companies Chitaroni rhymes off include First Cobalt Inc., Lico Energy Metals, and Battery Mineral Resources, an Australian company which entered into an agreement to purchase Tres-Or’s Fabre Cobalt-Silver Property in August. In November, another Australian company with property in Cobalt, Ophiolite Consultants Pty., was acquired by Equator Resources Limited.

“It should be pretty busy here for the next several years,” said Chitaroni. “It’s going to be very difficult to get anything into production in the short term – it usually takes 18 months to three years to commission a new mine – so I think this could be a good long-term opportunity for the Cobalt area.”

Having silver as a by-product would be the icing on the cake and “put Cobalt over the top,” he said.

.jpg;w=120;h=80;mode=crop)