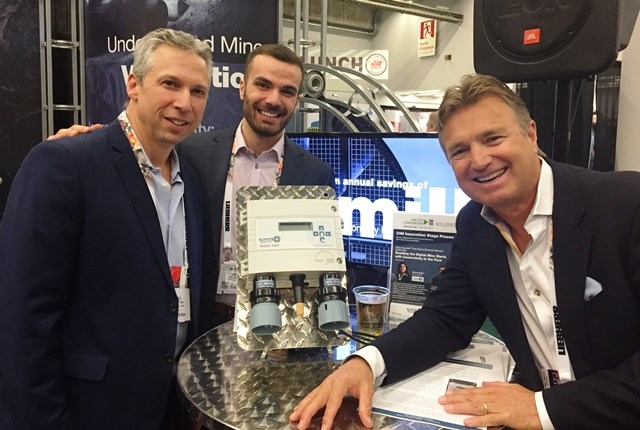

Sudbury based Maestro Digital Mine launched a new digital IIoT (Industrial Internet of Things) solution for mining ventilation at the annual CIM convention held in Montreal in April.

The new device, the the Zephyr AQS™, is described as a compact, low cost environmental air quality monitoring station for underground mines, said a company news release.

The Zephyr device connects directly to an industrial network without the requirement of adding expensive and complex programmable logic controllers (PLCs) and several analog based instruments, said the company. Since it is a digital device, not only are the real time environmental conditions reported back to surface via a single Ethernet connection, but all the advanced diagnostic data is available too assuring maximum uptime as well.

Michael Gribbons, Maestro's Vice President Sales and Marketing, told the audience at the launch event that, “the Zephyr AQS™ was developed to satisfy 75% of all the air monitoring requirements of a modern mine. Airflow rate, airflow direction, gas levels, barometric pressure and wet/dry bulb temperatures can be measured in real time and now affordably.”

Gribbons went on to explain that the Zephyr is designed for any mine aiming to increase production, improve miner worker safety and reduce energy by monitoring and controlling ventilation air in an underground operation.

“The first step of working to control ventilation is the requirement of measurement. Only then can you start to understand and drive value to increasing production by getting the miners back to the face quicker and safer. Or reducing the energy demand by providing enough ventilation air to the areas of the mine that need it and reducing air to the non-working areas of the mine.”

Like all Maestro’s solutions, the Zephyr AQS™ is fully digital solution that can be plugged into a network switch without the requirement of expensive PLCs, PLC cabinets and all the associated wiring, terminations, software and complex labour for integration into the network, said the company release.

Based on direct customer feedback, Maestro’s digital products save mining companies on average 40-60% of CAPEX compared to conventional monitoring solutions. All Maestro solutions are provided with lifetime, free firmware updates. The full savings to mining clients is in the range of 70-80% over the full life cycle with no hidden hooks or costs to bear in the OPEX maintenance cycle, said the company.

Maestro said the Zephyr AQS™ air quality station features three fully configurable sensor inputs that can be freely mixed and matched according to the customer’s requirements. Like the Vigilante AQS™, the Zephyr AQS™ will be configured through built-in web pages similar to that of a home network router. All the sensors are connected to the Zephyr AQS™ electronics digitally supported by the way that the Zephyr AQS™ communicates over the mine’s network using standard network protocols. Maestro fully supports both of the two most popular network communication protocols - Modbus TCP/IP and EtherNet/IP™. Alternately, the Zephyr AQS™ offers on-board analog outputs (3 x 4-20 mA) and two relay outputs to tie into legacy systems.